WD-SJ501 Sintering flux for submerged arc welding

Subclassification:

· Carbon Steel

Enquiry hotline:

- Product description

-

- Commodity name: WD-SJ501 Sintering flux for submerged arc welding

- Commodity ID: 1057227521411342336

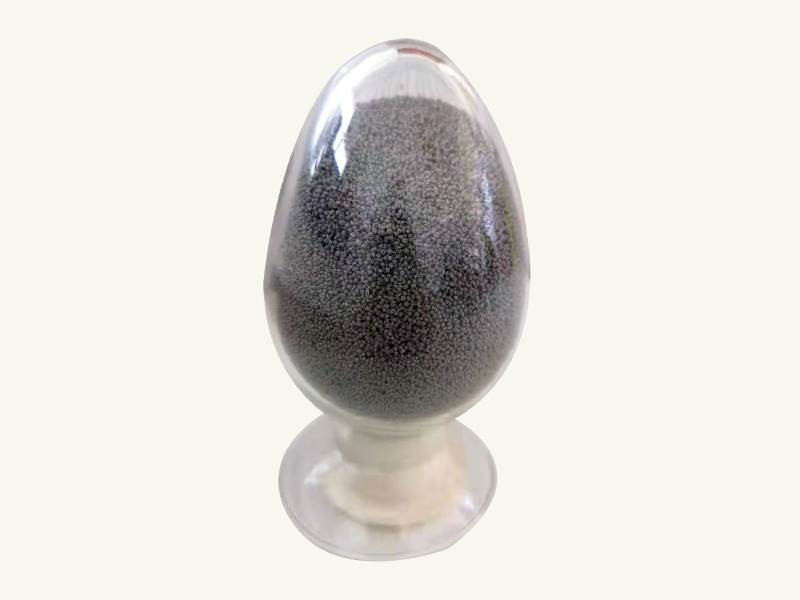

WD-SJ105 is a fluoro-alkali type sintering flux with an alkalinity of about 3.2. It has the appearance of gray-black spherical particles of 10-60 mesh (2.0-0.28mm).

Standards:

GB/T5293 S 43A 0 AR-SU08A AWS A5.17 F6A0-EL8 F6A2-EM12 ISO 14174-S A AR 1

Introduction:

WD-SJ105 is a fluoro-alkali type sintering flux with an alkalinity of about 3.2. It has the appearance of gray-black spherical particles of 10-60 mesh (2.0-0.28mm). The flux has advantages as follows: has good moisture absorption resistance; high particle strength; small loose packing density; low flux consumption during welding. The maximum welding current of the flux in the welding process up to 1200A and has arc stability; the formation of short slag after welding; narrow gap de-slagging is easy; do not drip slag in welding small diameter cylinders; beautiful weld formation; pure deposited metal; low SiO2 content, reducing the transition of silicon; has a high low temperature impact toughness. The wire is connected to the positive electrode when DC welding. With the corresponding wire, multi-layer welding, double-sided single-pass welding, multi-wire welding and narrow gap submerged arc welding, etc., can be used to weld higher strength marine steel, pressure vessel steel, pipeline steel, marine platforms and fine grain structural steel for important welded products.

Applications:

It can be used for butt and fillet welds of ships, pressure vessels, storage tanks, steel structures, bridges, spiral welded pipes and other structures.

Flux chemical composition reference value(%):

SiO2+TiO2

CaO+MgO

Al203+MnO

CaF2

S

P

9.5

33.5

20.4

36.6

0.024

0.028

Reference values for mechanical properties of molten metal:

Mating wireYield strength

(MPa)Tensile strength

(MPa)Elongation

(%)KV2 (J)

-20°C

-40°C

H08A

420

520

33

80

60

H10Mn2

450

560

30

85

65

Notice:1. The flux shall be baked at 300-350°C for 2 hours before use.

2. Rust, oil, water and other impurities should be removed from the welded parts before welding.

Key words:- wd-sj501

- welding

- flux

CONTACT US

Mobile phone:13898363063

Copyright© 2023 Jinzhou Wonder Welding Material Co., Ltd. all rights reserved. SEO Business license

Powered by:www.300.cn jinzhou.300.cn